INC.

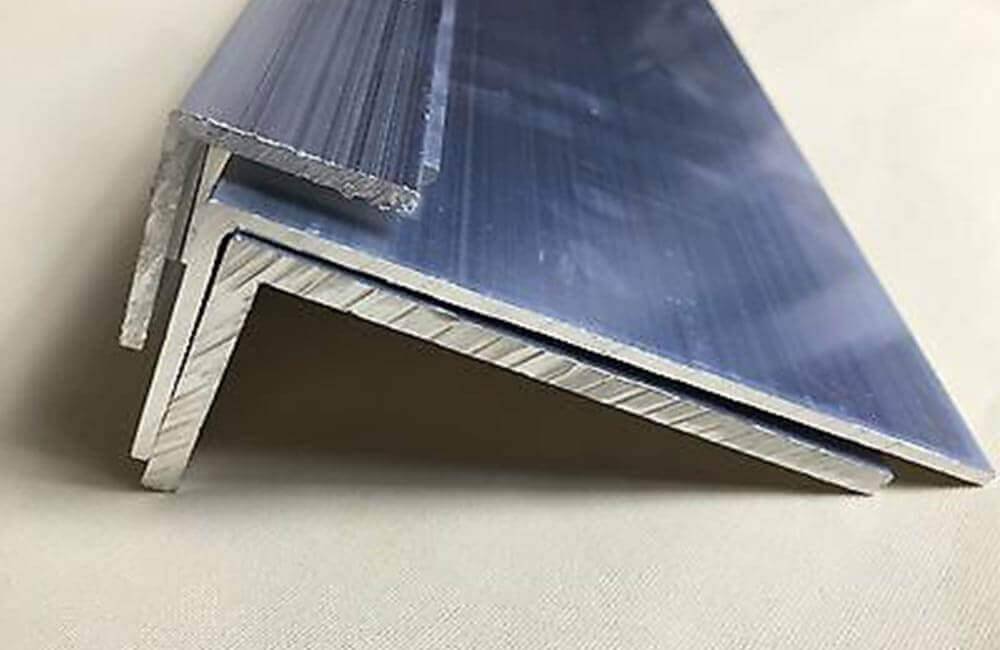

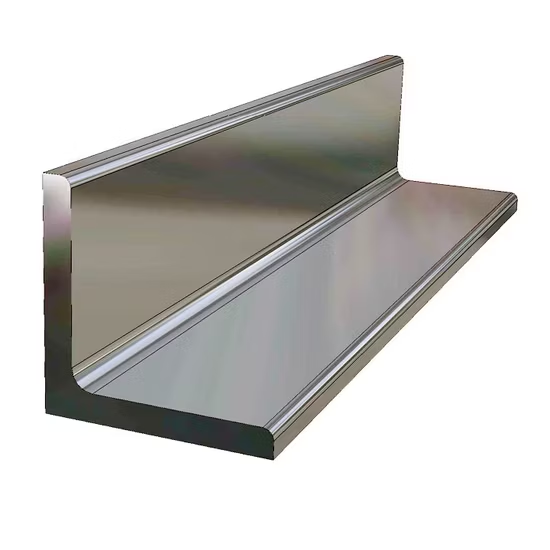

Aluminium Alloy 1200 Angles are manufactured from commercially pure aluminium, containing a minimum of 99.0% aluminium. This grade is widely recognized for its excellent corrosion resistance, good thermal and electrical conductivity, and outstanding workability. Owing to its lightweight nature and easy fabrication properties, Aluminium 1200 Angles are extensively used in architectural frameworks, structural applications, electrical components, food processing equipment, and chemical processing industries. Aluminium 1200 offers excellent weldability and is highly suitable for cold working operations such as bending, forming, cutting, and shaping. Although it is a non-heat treatable alloy with moderate mechanical strength, it performs reliably in environments where corrosion resistance, smooth surface finish, and durability are essential. These angles can be supplied in various tempers and finishes including mill finish, anodized, polished, and brushed surfaces to meet diverse industrial and decorative requirements. Aluminium 1200 Angles are ideal for both indoor and outdoor applications, ensuring long service life with minimal maintenance. Custom dimensions, thicknesses, lengths, and finishes can be provided as per specific client requirements for commercial and industrial projects.

ASME SB221 Aluminium 1200 L Angles, Aluminium Alloy 1200 L Angles, Aluminium Equal L 1200 Angles, Aluminum 1200 L Angles, Aluminium A91200 L Angle Supplier in Mumbai, H14 Temper Aluminum 1200 Unequal L Angles, ASTM B211 Aluminium 1200 Anodized L Angles Stockist, 1200 Aluminium L Angles Exporter.

ASME SB221 Aluminium 1200 T Angles, Aluminium Alloy 1200 T Angles, Aluminium Equal T 1200 Angles, Aluminum 1200 T Angles, Aluminium A91200 T Angle Supplier in Mumbai, H14 Temper Aluminum 1200 Unequal T Angles, ASTM B211 Aluminium 1200 Anodized T Angles Stockist, 1200 Aluminium T Angles Exporter.

| STANDARD | UNS | WERKSTOFF NR. |

| 1200 | A91200 | 3.0205 |

| Aluminium 1200 | Fe | Si | Cu | Mn | Mg | Zn | Ti | Al |

| 0.50 Max | 0.50 Max | 0.05 Max | 0.05 Max | 0.05 Max | 0.10 Max | 0.05 Max | 99.00 Min |

| Alloy | Temper | UTS (MPa) | % Elongation | |||

| Min | Max | 0.5 mm - 0.8 mm | 0.81 mm - 1.30 mm | 1.30 mm - above | ||

| 1200 | O | 60 | 85 | 30 | 30 | 35 |

| H12 | 85 | 120 | 6 | 6 | 8 | |

| H14 | 95 | 125 | 5 | 5 | 6 | |

| H16 | 100 | 135 | 4 | 4 | 5 | |

| H18 | 130 | --- | 3 | 3 | 3 | |

| Properties | Metric |

|---|---|

| Density | 2.71 Mg/m³ |

| Melting Point | 643°C – 657°C |

| Specific Heat (100°C) | 900 J/kg·K |

| Thermal Conductivity | ~230 W/m·K |

| Electrical Conductivity | ~59% IACS |

| 1050 | 1060 | 1070 | 1100 | 2014 |

| 5005 | 5052 | 5754 | 5082 | 5083 |

| 5754 | 5083 | 5086 | 6061 | 6063 |

| 6082 | 6083 | 7050 | 7075 |

| Aluminium 1050 Angles Exporters: | ||||

|---|---|---|---|---|

| Saudi Arabia | Oman | Kuwait | Netherlands | Iran |

| Bahrain | Qatar | UAE | Africa | China |

| Nigeria | Mexico | Canada | Venezuela | United Kingdom |

| United States | South Africa | Malaysia | Bangladesh | Turkey |

| Singapore | Sri Lanka | Australia | Brazil | Germany |

| France | Italy | South Korea | Poland | Belgium |

| Countries we have exported our products to: | |||||

|---|---|---|---|---|---|

| Bengaluru | Mumbai | Chennai | Hyderabad | Kolkata | Pune |

| New Delhi | Ahmedabad | Jaipur | Surat | Salem | Gandhinagar |

| Bhiwandi | Tiruppur | Sivakasi | Jamnagar | Thiruvananthapuram | Rajahmundry |

| Bhubaneswar | Vijaywada | Firozabad | Bokaro Steel City | Rajkot | Bharuch |

| Panna | Raipur | Cochin | Ludhiana | Panipat | Durgapur |

| Peenya | Pimpri-Chinchwad | Channapatna | Kharagpur | Nashik | Bareilly |

| Varanasi | Haldia | Rourkela | Bangalore | Moradabad | Indore |

| Visakhapatnam | Trivandrum | Pithampur | Dibrugarh | Angul | Gwalior |

| Coimbatore | Kannur | Nagpur | Vadodara | Rudrapur | Noida |

| Agra | Bhagalpur | Jamshedpur | Bhilai | Lucknow | Kanpur |

| Thane | Bhopal | Sri City | Bareilly | Hosdurg | Pithampur |