INC.

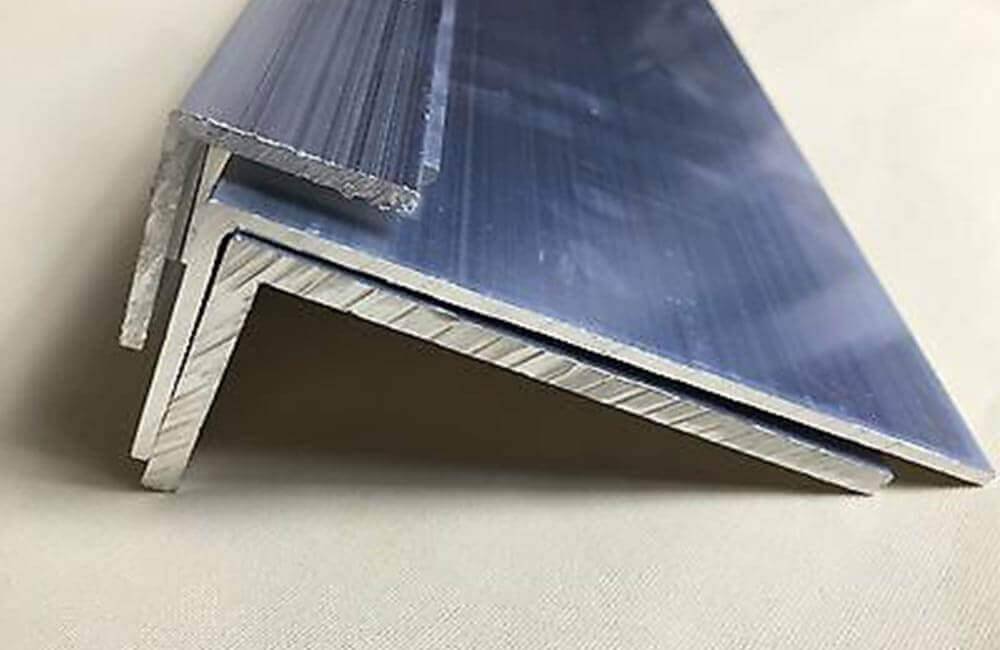

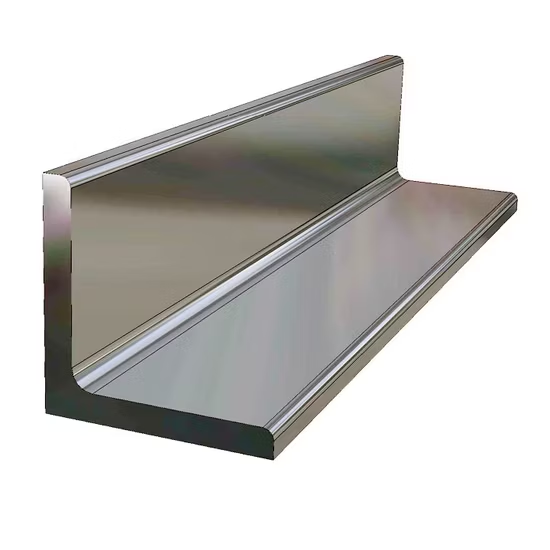

Aluminium 5025 Angles are manufactured from Aluminium Alloy 5025, a non-heat-treatable, magnesium-based alloy known for its excellent corrosion resistance, smooth surface finish, and good formability. This alloy is ideal for applications where durability, appearance, and resistance to environmental exposure are critical. Aluminium 5025 Angle sections offer moderate strength and good workability, making them perfect for architectural structures, decorative components, marine environments, signage, cladding systems, and general fabrication projects. The alloy is highly suitable for anodizing and other surface treatments, producing a uniform, high-quality finish. These angles exhibit excellent weldability and are suitable for cold working processes such as bending, forming, cutting, and machining. While non-heat-treatable, Aluminium 5025 delivers consistent mechanical performance and superior resistance to atmospheric and marine corrosion. They are commonly supplied in tempers such as H12, H14, and H24 to meet structural and fabrication requirements. Aluminium 5025 Angles are suitable for both indoor and outdoor applications and are widely used in architectural panels, building frameworks, transportation interiors, food processing equipment, chemical handling components, and marine fittings. Their lightweight nature and clean surface finish ensure long service life with minimal maintenance. We supply Aluminium 5025 Angles in custom sizes, lengths, thicknesses, and tempers as per client specifications, ensuring high quality, dimensional accuracy, and compliance with international standards for commercial and industrial projects.

ASME SB211 Aluminium 5052 L Angles, Aluminium Alloy L 5052 Angles, Aluminium Equal L 5052 Angles, Aluminum 5052 L Angles, Aluminium A95052 L Angle Supplier in Mumbai, H32 Temper Aluminum 5052 Unequal L Angles, Aluminium 3.3523 L Angles, ASTM B211 Aluminium 5052 Anodize L Angles Stockist, 5052 Aluminium L Angles Exporter.

ASME SB211 Aluminium 5052 T Angles, Aluminium Alloy T 5052 Angles, Aluminium Equal T 5052 Angles, Aluminum 5052 T Angles, Aluminium A95052 T Angle Supplier in Mumbai, H32 Temper Aluminum 5052 Unequal T Angles, Aluminium 3.3523 T Angles, ASTM B211 Aluminium 5052 Anodize T Angles Stockist, 5052 Aluminium T Angles Exporter.

| European Standard | OLD | WNr | UNS | ISO | USA (AA) | GERMANY (DIN) |

| AW-AlMg2,5 | AG2,5C | 3.3523 | A95052 | AlMg2,5 | 5052 | AlMg2,5 |

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

| 0.50 | 0.50 | 3.8/4.9 | 0.30/0.9 | 1.2/1.8 | 0.10 | 0.25 | 0.15 | Balance |

| Hardness, Brinell | Poisson's Ratio | Melting Point | Electrical Resistivity | Modulus of Elasticity | Specific Heat |

| 47 | 0.33 | 607 - 649 °C | 4.99e-006 ohm-cm | 70.3 GPa | 0.88 J/g-°C |

| Property | Metric Value |

|---|---|

| Density | 2.68 g/cm³ |

| Melting Point | 600 – 645°C |

| Specific Heat Capacity (at 25°C) | 900 J/kg·K |

| Thermal Conductivity | 135 W/m·K |

| Electrical Resistivity | 0.045 µΩ·m |

| 1050 | 1060 | 1070 | 1100 | 2014 |

| 5005 | 5052 | 5754 | 5082 | 5083 |

| 5754 | 5083 | 5086 | 6061 | 6063 |

| 6082 | 6083 | 7050 | 7075 |

| Aluminium 2014 Angles Exporters: | ||||

|---|---|---|---|---|

| Saudi Arabia | Oman | Kuwait | Netherlands | Iran |

| Bahrain | Qatar | UAE | Africa | China |

| Nigeria | Mexico | Canada | Venezuela | United Kingdom |

| United States | South Africa | Malaysia | Bangladesh | Turkey |

| Singapore | Sri Lanka | Australia | Brazil | Germany |

| France | Italy | South Korea | Poland | Belgium |

| Countries we have exported our products to: | |||||

|---|---|---|---|---|---|

| Bengaluru | Mumbai | Chennai | Hyderabad | Kolkata | Pune |

| New Delhi | Ahmedabad | Jaipur | Surat | Salem | Gandhinagar |

| Bhiwandi | Tiruppur | Sivakasi | Jamnagar | Thiruvananthapuram | Rajahmundry |

| Bhubaneswar | Vijaywada | Firozabad | Bokaro Steel City | Rajkot | Bharuch |

| Panna | Raipur | Cochin | Ludhiana | Panipat | Durgapur |

| Peenya | Pimpri-Chinchwad | Channapatna | Kharagpur | Nashik | Bareilly |

| Varanasi | Haldia | Rourkela | Bangalore | Moradabad | Indore |

| Visakhapatnam | Trivandrum | Pithampur | Dibrugarh | Angul | Gwalior |

| Coimbatore | Kannur | Nagpur | Vadodara | Rudrapur | Noida |

| Agra | Bhagalpur | Jamshedpur | Bhilai | Lucknow | Kanpur |

| Thane | Bhopal | Sri City | Bareilly | Hosdurg | Pithampur |