INC.

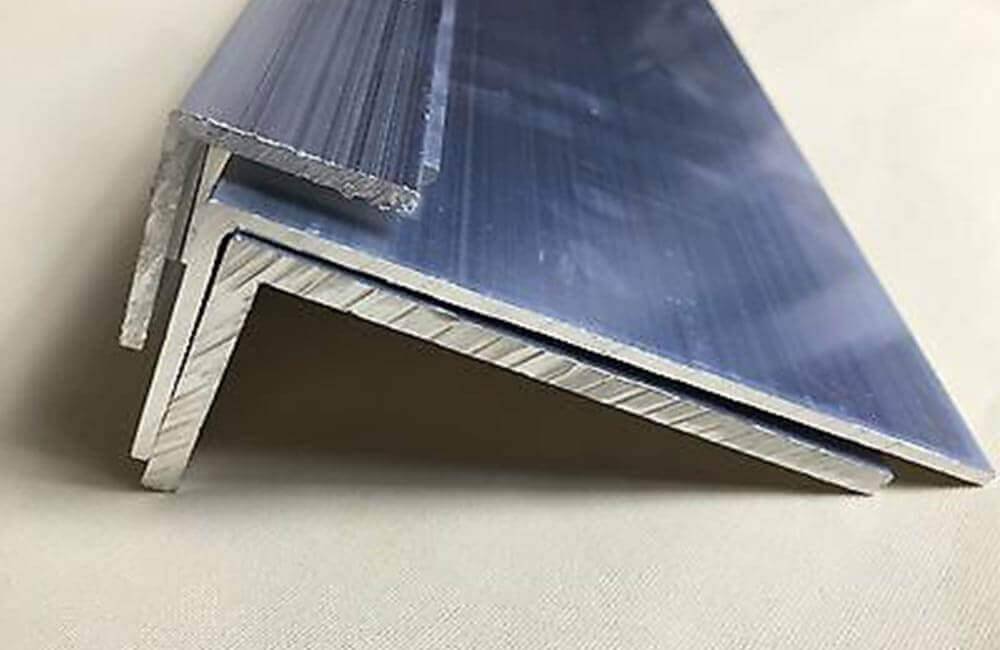

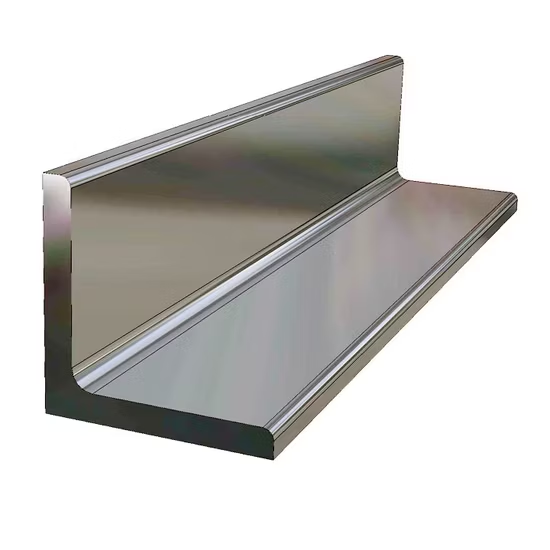

Aluminium Alloy 2007 Angles are manufactured from a high-strength aluminium-copper alloy known for its excellent machinability and good mechanical properties. This grade is widely used in applications requiring precision machining and high-performance structural components. Due to its strength, durability, and excellent chip formation during machining, Aluminium 2007 Angles are commonly used in mechanical engineering, automotive parts, aerospace components, precision fittings, and industrial equipment. Aluminium 2007 offers good machinability and moderate corrosion resistance. It is a heat-treatable alloy that achieves higher strength through appropriate heat treatment processes. While it has lower corrosion resistance compared to commercially pure aluminium grades, it performs reliably in controlled environments and can be enhanced with surface treatments such as anodizing or protective coatings. The alloy is well-suited for drilling, turning, milling, and other high-speed machining operations. Aluminium 2007 Angles can be supplied in various tempers and finishes including mill finish, anodized, or customized surface treatments as per application requirements. Suitable for structural and precision engineering applications, these angles provide excellent dimensional stability and long service life. Custom sizes, thicknesses, and lengths can be manufactured as per specific industrial and commercial project specifications.

ASME SB221 Aluminium 2007 L Angles, Aluminium Alloy 2007 L Angles, Aluminium Equal L 2007 Angles, Aluminum 2007 L Angles, Aluminium A92007 L Angle Supplier in Mumbai, T6 Temper Aluminum 2007 Unequal L Angles, ASTM B221 Aluminium 2007 Anodized L Angles Stockist, 2007 Aluminium L Angles Exporter.

ASME SB221 Aluminium 2007 T Angles, Aluminium Alloy 2007 T Angles, Aluminium Equal T 2007 Angles, Aluminum 2007 T Angles, Aluminium A92007 T Angle Supplier in Mumbai, T6 Temper Aluminum 2007 Unequal T Angles, ASTM B221 Aluminium 2007 Anodized T Angles Stockist, 2007 Aluminium T Angles Exporter.

| STANDARD | UNS | WERKSTOFF NR. |

| 2007 | A92007 | 3.1645 |

| Aluminium 2007 | Si | Fe | Cu | Mn | Mg | Zn | Pb | Bi | Al |

| 0.20 - 0.80 | 0.70 Max | 3.30 - 4.60 | 0.40 - 1.00 | 0.40 - 1.80 | 0.80 Max | 0.20 - 0.80 | 0.20 - 0.60 | Balance |

| Alloy | Temper | UTS (MPa) | % Elongation | |||

| Min | Max | Up to 3 mm | 3 mm - 6 mm | Above 6 mm | ||

| 2007 | T3 | 370 | 430 | 6 | 8 | 10 |

| T4 | 350 | 410 | 8 | 10 | 12 | |

| T6 | 400 | 480 | 5 | 6 | 8 | |

| Properties | Metric |

|---|---|

| Density | 2.78 Mg/m³ |

| Melting Point | 500°C – 635°C |

| Specific Heat (20°C) | 875 J/kg·K |

| Thermal Conductivity | ~150 W/m·K |

| Electrical Conductivity | ~40% IACS |

| 1050 | 1060 | 1070 | 1100 | 2014 |

| 5005 | 5052 | 5754 | 5082 | 5083 |

| 5754 | 5083 | 5086 | 6061 | 6063 |

| 6082 | 6083 | 7050 | 7075 |

| Aluminium 2007 Angles Exporters: | ||||

|---|---|---|---|---|

| Saudi Arabia | Oman | Kuwait | Netherlands | Iran |

| Bahrain | Qatar | UAE | Africa | China |

| Nigeria | Mexico | Canada | Venezuela | United Kingdom |

| United States | South Africa | Malaysia | Bangladesh | Turkey |

| Singapore | Sri Lanka | Australia | Brazil | Germany |

| France | Italy | South Korea | Poland | Belgium |

| Countries we have exported our products to: | |||||

|---|---|---|---|---|---|

| Bengaluru | Mumbai | Chennai | Hyderabad | Kolkata | Pune |

| New Delhi | Ahmedabad | Jaipur | Surat | Salem | Gandhinagar |

| Bhiwandi | Tiruppur | Sivakasi | Jamnagar | Thiruvananthapuram | Rajahmundry |

| Bhubaneswar | Vijaywada | Firozabad | Bokaro Steel City | Rajkot | Bharuch |

| Panna | Raipur | Cochin | Ludhiana | Panipat | Durgapur |

| Peenya | Pimpri-Chinchwad | Channapatna | Kharagpur | Nashik | Bareilly |

| Varanasi | Haldia | Rourkela | Bangalore | Moradabad | Indore |

| Visakhapatnam | Trivandrum | Pithampur | Dibrugarh | Angul | Gwalior |

| Coimbatore | Kannur | Nagpur | Vadodara | Rudrapur | Noida |

| Agra | Bhagalpur | Jamshedpur | Bhilai | Lucknow | Kanpur |

| Thane | Bhopal | Sri City | Bareilly | Hosdurg | Pithampur |