INC.

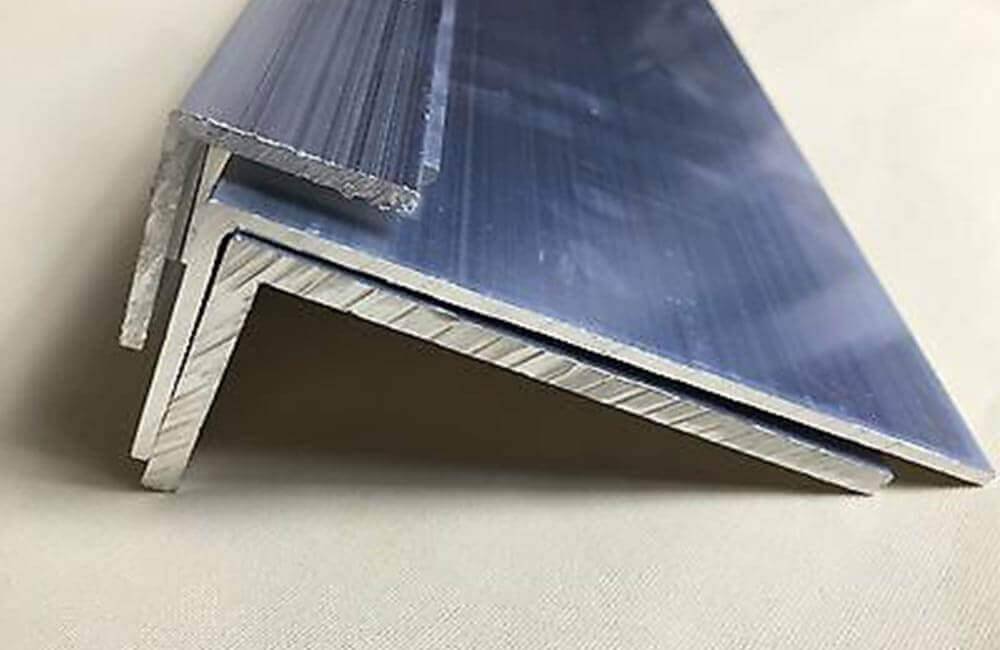

Aluminium 2007 Channels are manufactured from Aluminium Alloy 2007, a high-strength aluminum–copper alloy known for its excellent machinability, good mechanical strength, and reliable performance in precision engineering applications. With a significant copper content, Alloy 2007 offers higher strength compared to commercially pure aluminium grades, making it suitable for components that require enhanced load-bearing capability along with dimensional stability. These channels are particularly suited for applications where strength, machinability, and accuracy are critical. Aluminium 2007 channels provide outstanding machinability and can be easily turned, milled, drilled, and machined to tight tolerances. Although its corrosion resistance is lower than that of pure aluminium alloys, it can be improved through surface treatments such as anodizing or protective coatings. Alloy 2007 channels are typically supplied in T4 and T6 tempers, ensuring consistent mechanical properties, excellent surface finish, and dependable performance in precision-fabricated components. Applications of Aluminium 2007 channels include precision engineering components, automotive and aerospace parts, mechanical assemblies, machine tool structures, fastener systems, and industrial equipment where high strength and excellent machinability are required. Their ability to maintain dimensional accuracy under load makes them ideal for medium to high-stress applications. We supply Aluminium 2007 channels in custom sizes, lengths, thicknesses, tempers, and surface finishes as per client specifications, ensuring precise dimensional tolerances, consistent quality, and full compliance with international standards for industrial, mechanical, and engineering channel applications.

| European Standard | BS (OLD) | USA (AA) | Germany (DIN) | ISO | IS | Canadian |

|---|---|---|---|---|---|---|

| EN AW-2007 | — | 2007 | AlCu4PbMgMn (DIN 3.1645) | AlCu4PbMgMn | IS 733 – 2007 | 2007 |

| Alloy | Fe | Si | Mg | Mn | Cu | Zn | Ti | Cr | Each | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| 2007 (min) | — | — | 0.40 | 0.40 | 3.30 | — | — | — | — | remainder |

| 2007 (max) | 0.80 | 0.80 | 1.80 | 1.80 | 5.00 | 0.30 | 0.20 | 0.10 | 0.05 | remainder |

| Alloy | Temper | UTS (MPa) | % Elongation | |||

| Min | Max | 0.5 mm – 0.8 mm | 0.81 mm – 1.30 mm | 1.30 mm – above | ||

| 2007 | O | 150 | 220 | 12 | 14 | 16 |

| T4 | 340 | 420 | 8 | 10 | 12 | |

| T6 | 430 | 500 | 6 | 8 | 10 | |

| Properties | Metric |

|---|---|

| Density | 2.78 Mg/m³ |

| Melting Point | 502°C – 638°C |

| Specific Heat (100°C) | 875 J/kg·K |

| 1100 | 2014 | 2017 | 2024 | 3003 |

| 5086 | 5052 | 5754 | 5082 | 5083 |

| 6061 | 6063 | 6082 |

| Aluminium 2007 Channels Exporters: | ||||

|---|---|---|---|---|

| Saudi Arabia | Oman | Kuwait | Netherlands | Iran |

| Bahrain | Qatar | UAE | Africa | China |

| Nigeria | Mexico | Canada | Venezuela | United Kingdom |

| United States | South Africa | Malaysia | Bangladesh | Turkey |

| Singapore | Sri Lanka | Australia | Brazil | Germany |

| France | Italy | South Korea | Poland | Belgium |

| Countries we have exported our products to: | |||||

|---|---|---|---|---|---|

| Bengaluru | Mumbai | Chennai | Hyderabad | Kolkata | Pune |

| New Delhi | Ahmedabad | Jaipur | Surat | Salem | Gandhinagar |

| Bhiwandi | Tiruppur | Sivakasi | Jamnagar | Thiruvananthapuram | Rajahmundry |

| Bhubaneswar | Vijaywada | Firozabad | Bokaro Steel City | Rajkot | Bharuch |

| Panna | Raipur | Cochin | Ludhiana | Panipat | Durgapur |

| Peenya | Pimpri-Chinchwad | Channapatna | Kharagpur | Nashik | Bareilly |

| Varanasi | Haldia | Rourkela | Bangalore | Moradabad | Indore |

| Visakhapatnam | Trivandrum | Pithampur | Dibrugarh | Angul | Gwalior |

| Coimbatore | Kannur | Nagpur | Vadodara | Rudrapur | Noida |

| Agra | Bhagalpur | Jamshedpur | Bhilai | Lucknow | Kanpur |

| Thane | Bhopal | Sri City | Bareilly | Hosdurg | Pithampur |