INC.

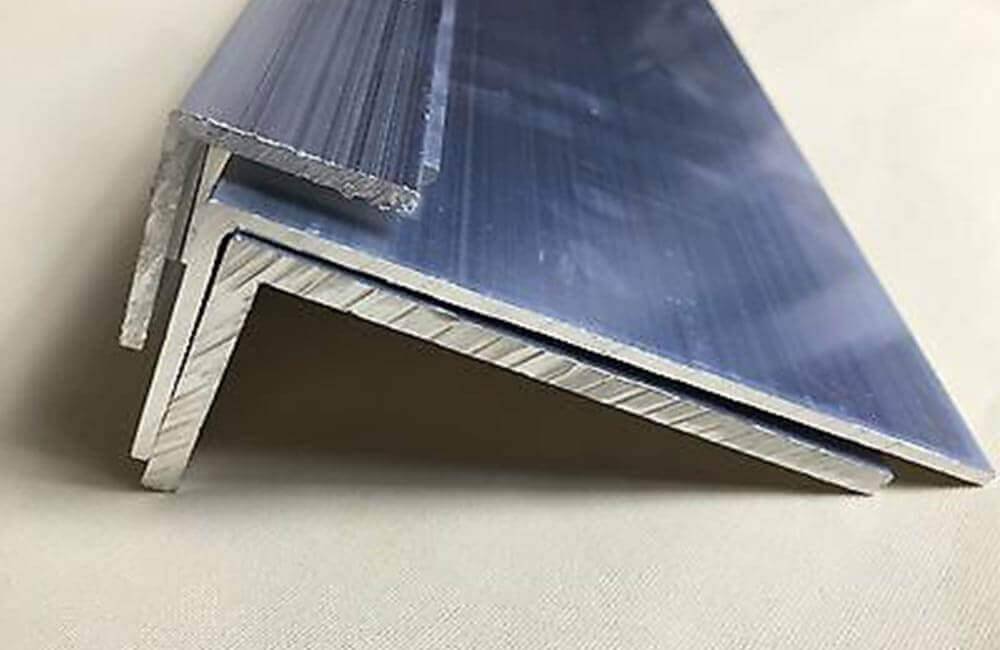

Aluminium 7050 Channels are manufactured from Aluminium Alloy 7050, a high-strength aluminium–zinc alloy specifically developed for superior performance in thick sections and high-stress structural applications. Alloy 7050 contains controlled amounts of zinc, magnesium, and copper, providing excellent strength, fracture toughness, and resistance to stress corrosion cracking. These channels are especially suited for applications where high load-bearing capacity, dimensional stability, and long-term structural reliability are critical. Aluminium 7050 channels offer very good machinability and can be accurately milled, drilled, and machined to tight tolerances, making them ideal for precision engineering and aerospace applications. Compared to Alloy 7075, Aluminium 7050 provides improved resistance to stress corrosion and better performance in thicker cross-sections. Corrosion resistance can be further enhanced through anodizing, cladding, or protective surface coatings. Alloy 7050 channels are commonly supplied in T7451, T7651, and T6 tempers, ensuring consistent mechanical properties, high toughness, and dependable performance in demanding service conditions. Applications of Aluminium 7050 channels include aerospace structural components, aircraft wing and fuselage structures, defence and military equipment, high-stress mechanical assemblies, tooling plates, jigs and fixtures, and heavy-duty industrial machinery. Their superior strength-to-weight ratio, enhanced fracture toughness, and resistance to stress corrosion make them ideal for critical structural and safety-sensitive applications. We supply Aluminium 7050 channels in custom sizes, lengths, thicknesses, tempers, and surface finishes as per client specifications, ensuring precise dimensional tolerances, consistent quality, and full compliance with international standards for aerospace, defence, automotive, and high-performance engineering channel applications.

| European Standard | BS (OLD) | USA (AA) | Germany (DIN) | ISO | IS | Canadian |

|---|---|---|---|---|---|---|

| EN AW-7050 | — | 7050 | AlZn6CuMgZr (DIN) | AlZnCuMgZr | IS 733 – 7050 | 7050 |

| Alloy | Fe | Si | Mg | Mn | Cu | Zn | Ti | Cr | Each | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| 7050 (min) | — | — | 1.90 | — | 2.00 | 5.70 | — | — | — | remainder |

| 7050 (max) | 0.15 | 0.12 | 2.60 | 0.10 | 2.60 | 6.70 | 0.06 | 0.04 | 0.05 | remainder |

| Alloy | Temper | UTS (MPa) | % Elongation | |||

| Min | Max | 0.5 mm – 0.8 mm | 0.81 mm – 1.30 mm | 1.30 mm – above | ||

| 7050 | O | 210 | 270 | 14 | 16 | 18 |

| T6 | 480 | 540 | 7 | 9 | 11 | |

| T651 | 500 | 560 | 6 | 8 | 10 | |

| Properties | Metric |

|---|---|

| Density | 2.83 Mg/m³ |

| Melting Point | 477°C – 635°C |

| Specific Heat (100°C) | 960 J/kg·K |

| 1100 | 2014 | 2017 | 2024 | 3003 |

| 5086 | 5052 | 5754 | 5082 | 5083 |

| 6061 | 6063 | 6082 |

| Aluminium 7050 Channels Exporters: | ||||

|---|---|---|---|---|

| Saudi Arabia | Oman | Kuwait | Netherlands | Iran |

| Bahrain | Qatar | UAE | Africa | China |

| Nigeria | Mexico | Canada | Venezuela | United Kingdom |

| United States | South Africa | Malaysia | Bangladesh | Turkey |

| Singapore | Sri Lanka | Australia | Brazil | Germany |

| France | Italy | South Korea | Poland | Belgium |

| Countries we have exported our products to: | |||||

|---|---|---|---|---|---|

| Bengaluru | Mumbai | Chennai | Hyderabad | Kolkata | Pune |

| New Delhi | Ahmedabad | Jaipur | Surat | Salem | Gandhinagar |

| Bhiwandi | Tiruppur | Sivakasi | Jamnagar | Thiruvananthapuram | Rajahmundry |

| Bhubaneswar | Vijaywada | Firozabad | Bokaro Steel City | Rajkot | Bharuch |

| Panna | Raipur | Cochin | Ludhiana | Panipat | Durgapur |

| Peenya | Pimpri-Chinchwad | Channapatna | Kharagpur | Nashik | Bareilly |

| Varanasi | Haldia | Rourkela | Bangalore | Moradabad | Indore |

| Visakhapatnam | Trivandrum | Pithampur | Dibrugarh | Angul | Gwalior |

| Coimbatore | Kannur | Nagpur | Vadodara | Rudrapur | Noida |

| Agra | Bhagalpur | Jamshedpur | Bhilai | Lucknow | Kanpur |

| Thane | Bhopal | Sri City | Bareilly | Hosdurg | Pithampur |