INC.

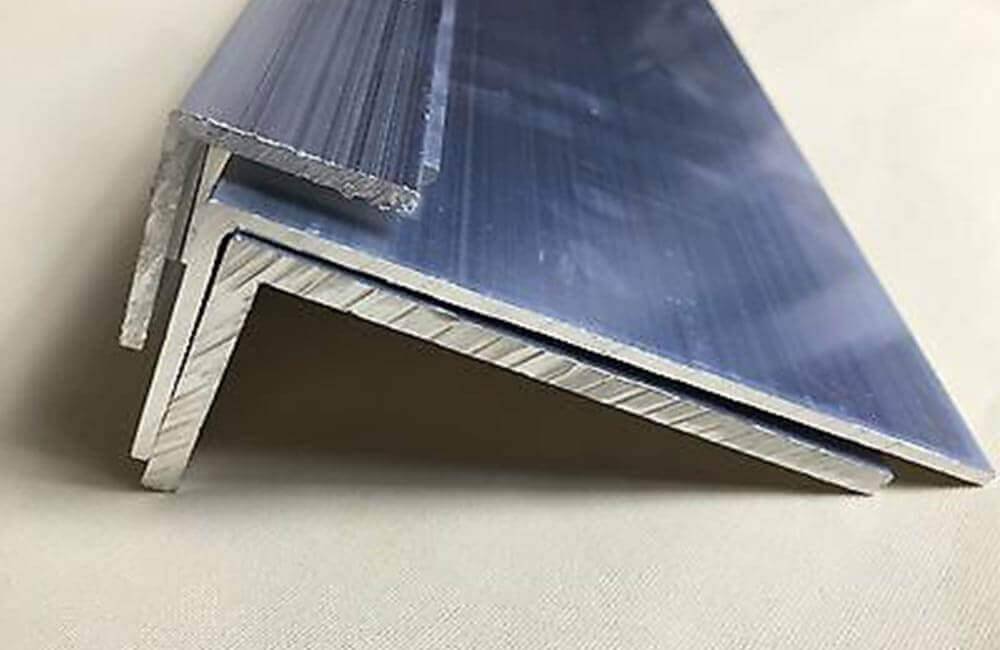

Aluminium 5754 Channels are manufactured from Aluminium Alloy 5754, a non-heat-treatable aluminum–magnesium alloy widely recognized for its excellent corrosion resistance, good formability, and moderate to high strength within the 5xxx series. This alloy provides outstanding resistance to marine atmospheres, saltwater, and industrial chemicals, making it ideal for applications where durability, structural integrity, and long service life are important. Aluminium 5754 Channels offer good machinability and excellent forming characteristics, enabling efficient fabrication through bending, cutting, drilling, rolling, and welding processes. Although the alloy is not heat-treatable, it gains strength through work hardening and delivers stable mechanical performance with a smooth surface finish. Aluminium 5754 Channels are commonly supplied in O, H111, H112, H114, and H321 tempers, ensuring consistent dimensional stability and reliable performance across industrial, marine, and transportation applications. Aluminium 5754 Channels are widely used in marine vessels, shipbuilding, offshore structures, transportation equipment, chemical tanks, HVAC systems, and general fabrication works. Their excellent corrosion resistance, lightweight nature, high strength, and weldability make them particularly suitable for harsh environments exposed to seawater, chemicals, and varying weather conditions. We supply Aluminium 5754 Channels in custom sizes, lengths, thicknesses, tempers, and surface finishes as per client specifications, ensuring precise dimensional accuracy, consistent quality, and compliance with international standards for marine, industrial, architectural, and commercial channel applications.

| European Standard | BS (OLD) | USA (AA) | Germany (DIN) | ISO | IS | Canadian |

|---|---|---|---|---|---|---|

| EN AW-5754 | — | 5754 | AlMg3 (DIN 3.3535) | AlMg3 | IS 5754 – 5754 | 5754 |

| Alloy | Fe | Si | Mg | Mn | Cu | Zn | Ti | Cr | Each | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| 5754 (min) | — | — | 3.0 | 0.4 | — | — | — | 0.10 | 0.05 | remainder |

| 5754 (max) | 0.40 | 0.40 | 3.5 | 1.0 | 0.10 | 0.25 | 0.15 | 0.25 | 0.15 | remainder |

| Alloy | Temper | UTS (MPa) | % Elongation | |||

| Min | Max | 0.5 mm – 0.8 mm | 0.81 mm – 1.30 mm | 1.30 mm – above | ||

| 5754 | O | 125 | 175 | 18 | 20 | 22 |

| H111 | 175 | 225 | 12 | 14 | 16 | |

| H112 | 180 | 230 | 10 | 12 | 14 | |

| H116 | 210 | 265 | 8 | 10 | 12 | |

| H321 | 225 | 280 | 6 | 8 | 10 | |

| Properties | Metric |

|---|---|

| Density | 2.66 Mg/m³ |

| Melting Point | 577°C – 638°C |

| Specific Heat (100°C) | 880 J/kg·K |

| 1100 | 2014 | 2017 | 2024 | 3003 |

| 5086 | 5052 | 5754 | 5082 | 5083 |

| 6061 | 6063 | 6082 |

| Aluminium 5086 Channels Exporters: | ||||

|---|---|---|---|---|

| Saudi Arabia | Oman | Kuwait | Netherlands | Iran |

| Bahrain | Qatar | UAE | Africa | China |

| Nigeria | Mexico | Canada | Venezuela | United Kingdom |

| United States | South Africa | Malaysia | Bangladesh | Turkey |

| Singapore | Sri Lanka | Australia | Brazil | Germany |

| France | Italy | South Korea | Poland | Belgium |

| Countries we have exported our products to: | |||||

|---|---|---|---|---|---|

| Bengaluru | Mumbai | Chennai | Hyderabad | Kolkata | Pune |

| New Delhi | Ahmedabad | Jaipur | Surat | Salem | Gandhinagar |

| Bhiwandi | Tiruppur | Sivakasi | Jamnagar | Thiruvananthapuram | Rajahmundry |

| Bhubaneswar | Vijaywada | Firozabad | Bokaro Steel City | Rajkot | Bharuch |

| Panna | Raipur | Cochin | Ludhiana | Panipat | Durgapur |

| Peenya | Pimpri-Chinchwad | Channapatna | Kharagpur | Nashik | Bareilly |

| Varanasi | Haldia | Rourkela | Bangalore | Moradabad | Indore |

| Visakhapatnam | Trivandrum | Pithampur | Dibrugarh | Angul | Gwalior |

| Coimbatore | Kannur | Nagpur | Vadodara | Rudrapur | Noida |

| Agra | Bhagalpur | Jamshedpur | Bhilai | Lucknow | Kanpur |

| Thane | Bhopal | Sri City | Bareilly | Hosdurg | Pithampur |