INC.

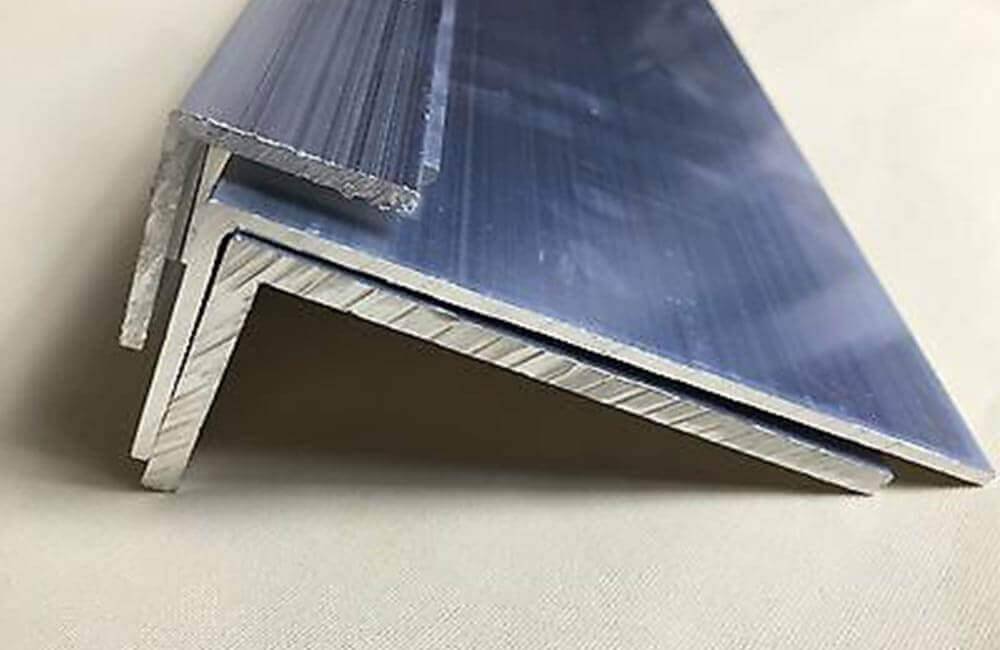

Aluminum 2014 Channels are manufactured from Aluminum Alloy 2014, a high-strength, heat-treatable aluminum-copper alloy widely recognized for its excellent mechanical strength, good fatigue resistance, and reliable performance in demanding structural environments. This alloy is well suited for applications where high load-bearing capacity and strength-to-weight ratio are critical, making it an ideal choice for heavy-duty industrial and engineering channel applications. Aluminum 2014 channels offer good machinability and high strength, allowing efficient fabrication through cutting, machining, drilling, and forming. While corrosion resistance is lower compared to pure aluminum grades, it can be improved through appropriate surface treatments and protective coatings. Aluminum 2014 channels are commonly supplied in T4 and T6 tempers, providing excellent mechanical stability and performance consistency for structural and precision applications. Aluminum 2014 channels are widely used in aerospace components, transportation structures, heavy machinery, tooling plates, military equipment, and high-stress industrial frameworks. Their superior strength, rigidity, and fatigue resistance make them suitable for applications where durability and structural integrity are essential. We supply Aluminum 2014 channels in custom sizes, lengths, thicknesses, tempers, and surface finishes as per client specifications, ensuring precise dimensional accuracy, consistent quality, and compliance with international standards for industrial, aerospace, and commercial channel applications.

| European Standard | BS (OLD) | USA (AA) | Germany (DIN) | ISO | IS | Canadian |

|---|---|---|---|---|---|---|

| EN AW-2017A | HE20 | 2017 | AlCu4MgSi (DIN 3.1325) | AlCu4MgSi | IS 737 – 2017 | 2017 |

| Alloy | Fe | Si | Mg | Mn | Cu | Zn | Ti | Cr | Each | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| 2017 (min) | — | 0.20 | 0.40 | 0.40 | 3.50 | — | — | — | 0.05 | remainder |

| 2017 (max) | 0.70 | 0.80 | 0.80 | 1.00 | 4.50 | 0.25 | 0.15 | 0.10 | 0.10 | remainder |

| Alloy | Temper | UTS (MPa) | % Elongation | |||

| Min | Max | 0.5 mm – 0.8 mm | 0.81 mm – 1.30 mm | 1.30 mm – above | ||

| 2017 | O | 165 | 220 | 14 | 16 | 18 |

| T3 | 345 | 425 | 8 | 10 | 12 | |

| T4 | 350 | 440 | 10 | 12 | 14 | |

| T6 | 390 | 470 | 6 | 8 | 10 | |

| Properties | Metric |

|---|---|

| Density | 2.79 Mg/m³ |

| Melting Point | 513°C – 640°C |

| Specific Heat (100°C) | 875 J/kg·K |

| 1100 | 2014 | 2017 | 2024 | 3003 |

| 5086 | 5052 | 5754 | 5082 | 5083 |

| 6061 | 6063 | 6082 |

| Aluminium 2017 Channels Exporters: | ||||

|---|---|---|---|---|

| Saudi Arabia | Oman | Kuwait | Netherlands | Iran |

| Bahrain | Qatar | UAE | Africa | China |

| Nigeria | Mexico | Canada | Venezuela | United Kingdom |

| United States | South Africa | Malaysia | Bangladesh | Turkey |

| Singapore | Sri Lanka | Australia | Brazil | Germany |

| France | Italy | South Korea | Poland | Belgium |

| Countries we have exported our products to: | |||||

|---|---|---|---|---|---|

| Bengaluru | Mumbai | Chennai | Hyderabad | Kolkata | Pune |

| New Delhi | Ahmedabad | Jaipur | Surat | Salem | Gandhinagar |

| Bhiwandi | Tiruppur | Sivakasi | Jamnagar | Thiruvananthapuram | Rajahmundry |

| Bhubaneswar | Vijaywada | Firozabad | Bokaro Steel City | Rajkot | Bharuch |

| Panna | Raipur | Cochin | Ludhiana | Panipat | Durgapur |

| Peenya | Pimpri-Chinchwad | Channapatna | Kharagpur | Nashik | Bareilly |

| Varanasi | Haldia | Rourkela | Bangalore | Moradabad | Indore |

| Visakhapatnam | Trivandrum | Pithampur | Dibrugarh | Angul | Gwalior |

| Coimbatore | Kannur | Nagpur | Vadodara | Rudrapur | Noida |

| Agra | Bhagalpur | Jamshedpur | Bhilai | Lucknow | Kanpur |

| Thane | Bhopal | Sri City | Bareilly | Hosdurg | Pithampur |